Struggling with Forklift Battery Choices? 3 Key Benefits of Lithium-Ion Explained

Selecting the right forklift battery isn’t just about power—it’s about productivity, safety, and long-term savings. If your operations are plagued by frequent charging breaks, rising maintenance bills, or safety incidents, it’s time to rethink your power source. In this guide, we’ll dive deep into lithium-ion vs. lead-acid forklift batteries, unpack their differences, and reveal why lithium-ion technology is transforming warehouses worldwide.

What Is a Lithium-Ion Forklift Battery?

Lithium-ion (Li-ion) forklift batteries are advanced energy storage systems that use lithium compounds as their core chemistry. These batteries are engineered for high performance in demanding environments, offering:

- Ultra-Fast Charging: 80% of the battery power can be restored in one hour of fast charging, and you don’t need to wait for cooling like old batteries when charging, you can use it directly.

- Maintenance-Free Operation: No need to add water regularly like lead-acid batteries, and no need to worry about acid leakage and corrosion of battery connectors. Basically, you don’t need to worry about it after installation.

- Longevity: It can be used for 8 to 10 years normally, and the number of charge and discharge times is twice that of ordinary lead-acid batteries, which can be charged about 3000-5000 times.

- Smart Technology: There is an intelligent management system in the battery that can monitor the battery voltage, temperature and charging status in real time to avoid overcharging and over-discharging.

Ideal for multi-shift operations, cold storage, and automated warehouses, lithium-ion forklift batteries deliver consistent power until full depletion, eliminating the "partial charge" penalties seen in lead-acid models.

What Is a Lead-Acid Battery?

Lead-acid batteries have powered forklifts for more than a century and are basically lead plates immersed in a sulfuric acid electrolyte. While affordable upfront, they come with significant drawbacks:

- Long Charging Times: A full charge takes 8 to 10 hours, followed by an 8-hour cool-down period, which greatly affects the continuous use efficiency of the equipment.

- High Maintenance: Weekly maintenance operations such as watering, checking acidity, and cleaning terminals increase manpower and material costs.

- Limited Lifespan: Usually replaced after 3 to 5 years (or 1,500 charge and discharge cycles), which not only leads to frequent equipment downtime, but also increases long-term operating costs.

- Energy Inefficiency: During the charging process, 20% to 30% of the energy is lost in the form of heat, which not only wastes resources but also places additional requirements on the battery's cooling system.

In addition, lead-acid batteries will experience a "voltage drop" phenomenon during use. That is, as the power is gradually depleted, the operating performance of the forklift will decline, affecting work efficiency and operational stability.

Lithium-Ion vs. Lead-Acid Forklift Battery Benefits

Let’s explore three game-changing advantages of lithium-ion forklift batteries:

1. Maximized Uptime, Minimized Downtime

- Lead-Acid: Requires 2–3 battery swaps per day for 24/7 operations. Charging downtime can cost $150–$300/hour in lost productivity.

- Lithium-Ion: Opportunity charging allows operators to recharge during breaks or shift changes. A 15-minute charge adds 2–3 hours of runtime.

Case Study: A Midwest distribution center reduced downtime by 40% after switching to lithium-ion, achieving 22 hours of daily operation.

2. Hidden Cost Savings You Can’t Ignore

Although the initial cost of lithium-ion batteries is higher, reaching 2 to 3 times that of lead-acid batteries, the total cost of ownership (TCO) is reduced by 30% to 50% within 10 years. This significant cost saving is mainly attributed to the following aspects:

- No Maintenance Labor: Lithium-ion battery forklifts can save more than 50 hours of maintenance time per year, which not only reduces labor costs but also improves equipment availability and work efficiency.

- Energy Efficiency:Lead-acid batteries lose 20% to 30% of their energy in the form of heat during the charging process, while lithium-ion batteries lose much less. This higher energy efficiency directly translates into lower electricity costs, saving users more operating costs.

- Space Savings: Lithium-ion batteries are 30% to 50% smaller than lead-acid batteries. In space-constrained environments such as warehouses and factories, this space saving is particularly important, which can improve overall operational efficiency and space utilization.

ROI Example: Taking a fleet of 100 forklifts as an example, using lithium-ion batteries instead of lead-acid batteries can save $1.2 million in energy and labor costs over ten years.

3. Safety Built for Modern Workplaces

Lead-acid batteries pose multiple risks:

- Hydrogen gas explosions during charging:

- Acid spills requiring hazmat cleanup.

- Ergonomic injuries from battery swaps (500–2,000 lbs each).

- Environmental pollution

- Waste disposal

Lithium-ion eliminates these hazards with:

- The sealed design does not release hydrogen during charging, thus eliminating the risk of explosion caused by hydrogen accumulation.

- Acid-free electrolyte is used internally, and the battery structure is sealed.

- The weight is 50-70% lighter than lead-acid batteries, and a modular design can be used for easy installation and replacement.

Lead-Acid vs. Lithium-Ion: Key Differences

| Factor | Lead-Acid | Lithium-Ion |

|---|---|---|

| Charging Infrastructure | Dedicated charging rooms required | Opportunity charging anywhere |

| Depth of Discharge | 50–60% (partial use to avoid damage) | 100% (no memory effect) |

| Temperature Performance | Capacity drops 30–40% in sub-zero temps | Stable output from -20°C to 60°C |

| Replacement Frequency | Every 3–5 years | Every 8–10 years |

| Environmental Impact | 98% recyclable but involves toxic lead | 80% recyclable with lower carbon footprint |

Lithium-Ion Forklift Batteries vs. Lead-Acid: Which Is Best for You?

Stick with Lead-Acid If:

- Your facility operates single shifts with low-intensity use.

- Immediate budget constraints are more important than long-term savings.

- You have dedicated staff and space for battery maintenance.

Upgrade to Lithium-Ion If:

- You run multi-shift or 24/7 operations (e.g., e-commerce fulfillment).

- Cold storage (-20°C) or high-heat environments degrade lead-acid performance.

- Safety compliance and sustainability are corporate priorities.

Pro Tip: Calculate your break-even point using this formula:

*(Lithium TCO – Lead-Acid TCO) / Annual Savings = Payback Period*

Most warehouses see ROI within 2–3 years.

Future-Proofing Your Fleet

The shift to lithium-ion aligns with broader industry trends:

- Automation Compatibility: The precise charging characteristics of lithium-ion batteries are a perfect match for the needs of automated equipment such as automated guided vehicles (AGVs).

- Energy Storage Integration: Forklift batteries can serve as a backup power source during peak grid demand, providing companies with a flexible energy solution.

- Regulatory Pressures: Regulators such as the OSHA and EPA continue to increase requirements for workplace safety and environmental protection.

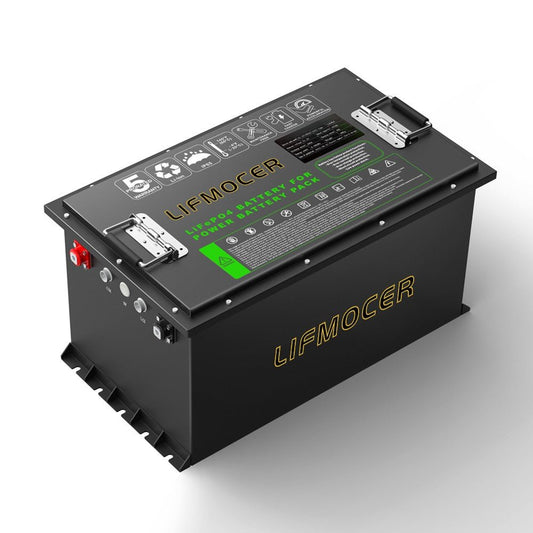

Contact LIFMOCER for Quality Lithium-Ion Forklift Batteries

At LIFMOCER, we engineer lithium-ion forklift batteries that redefine reliability:

- 🔥 HyperCharge Technology: 30-minute ultra-fast charging

- 🔋 Adaptive BMS: AI-driven diagnostics to prevent failures

- 🌍 EcoShield Design: 95% recyclable components

Why Choose LIFMOCER?

- 10-year performance warranty

- Custom voltage configurations (24V–96V)

- Free on-site energy audit

Frequently Asked Questions (FAQ)

Q: Which battery type is more cost-effective in the long run?

A: Lithium-ion batteries have a higher upfront cost but offer a total cost of ownership (TCO) that is 30–50% lower over 10 years compared to lead-acid batteries. This is due to their longer lifespan, lower maintenance requirements, and higher energy efficiency.

Q: Can lithium-ion batteries be used in extreme temperatures?

A: Yes, lithium-ion batteries maintain stable performance in temperatures ranging from -20°C to 60°C, making them suitable for cold storage and high-heat environments where lead-acid batteries may struggle.

Q: How long does it take to charge a lithium-ion forklift battery?

A: Lithium-ion batteries can achieve an 80% charge in under 1 hour and can be opportunity charged during breaks or shift changes, adding 2–3 hours of runtime with just a 15-minute charge.

Q: Are lithium-ion batteries safer than lead-acid batteries?

A: Yes, lithium-ion batteries eliminate many of the hazards associated with lead-acid batteries, such as hydrogen gas explosions, acid spills, and ergonomic injuries from battery swaps. They feature sealed, non-toxic designs and produce no emissions during charging.

Q: What is the lifespan of a lithium-ion forklift battery?

A: Lithium-ion forklift batteries typically last 8–10 years or 3,000–5,000 cycles, which is double the lifespan of lead-acid alternatives that usually last 3–5 years.

You May Need

LIFMOCER 48V 315Ah LiFePO4 Forklift Lithium Battery

- $2,599.99 USD

$3,099.99 USD- $2,599.99 USD

- Unit price

- / per

LIFMOCER Electric Forklift Lithium Battery 24V 280AH

- $1,499.99 USD

$2,299.99 USD- $1,499.99 USD

- Unit price

- / per

LIFMOCER 96V 210Ah LiFePO4 Golf Cart Rechargeable Batteries

- $2,699.99 USD

$3,599.99 USD- $2,699.99 USD

- Unit price

- / per

LIFMOCER 96V 315Ah Lithium Golf Cart Battery Deep Cycle

- $2,899.99 USD

$4,099.99 USD- $2,899.99 USD

- Unit price

- / per

LIFMOCER 72V 210Ah Golf Cart Lithium Batteries

- $2,499.99 USD

$3,199.99 USD- $2,499.99 USD

- Unit price

- / per